Efficient automated mixing equipment achieves rapid and even mixing, is suitable for a variety of materials, and improves production efficiency.

![]()

![]()

Price::$1,000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

Each mixing amount: 100-6000kg

Mixing speed: 15-60r/min

Voltage: 380V/220V/450V

Power: 13.5-75kw

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Construction works , Food & Beverage Shops

Commitment: 1Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

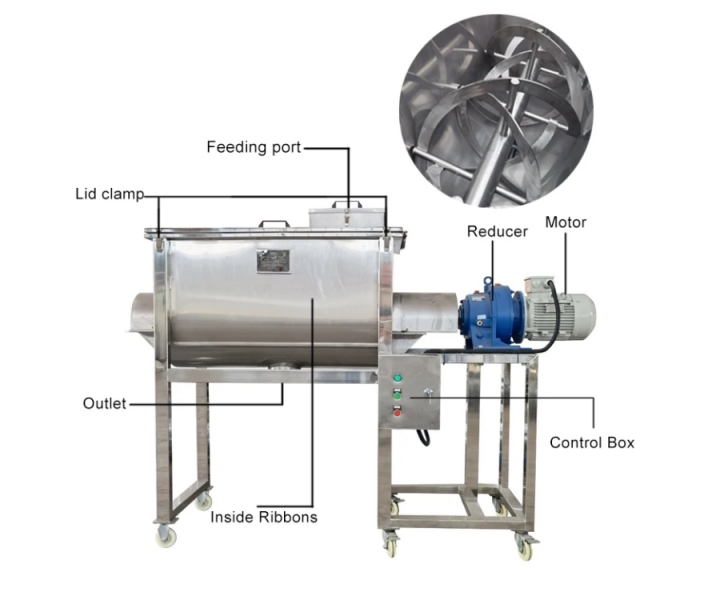

Automatic lifting hopper mixer is an advanced mixing equipment with the characteristics of automatic lifting function. It usually consists of a hopper and a stirring device, which can be used to mix different types of materials quickly and evenly. This mixer is widely used in chemical, pharmaceutical, food and other industries to improve production efficiency and product quality.

The automatic lifting function of this mixer allows it to adapt to the needs of different container heights and can easily adapt to different production scenarios. The operation is simple and convenient, and the operator can set and monitor through the control panel or computer. Its structure is strong and reliable, able to withstand long-term high-intensity work, and has corrosion resistance, making it suitable for handling various chemicals and food raw materials. The application of automatic lifting hopper mixer can effectively improve production efficiency, ensure the uniformity and consistency of products, and meet the needs of different industries for mixing processes.

Automatic lifting hopper mixers have a wide range of applications. Here are some common uses:

Chemical industry: In chemical production, automatic lifting hopper mixers can be used to mix various chemical substances, such as powders, granules, liquids, etc., to ensure the uniformity and consistency of reaction materials. It plays an important role in synthesis reactions, dissolution, solvent exchange and other processes.

Pharmaceutical industry: In pharmaceutical production, automatic lifting hopper mixers can be used to mix pharmaceutical powders, liquid medicines, preparations, etc. to ensure uniform distribution and mixing effect of pharmaceutical ingredients. It plays an important role in drug synthesis, drug formulation, drug dissolution and other links.

Food industry: In food processing, automatic lifting hopper mixers can be used to mix flour, seasonings, additives and other food raw materials to ensure the uniformity and taste of food. It plays an important role in bread making, condiment production, beverage processing, etc.

Other industries: The automatic lifting hopper mixer can also be used in cosmetics production, paint production, pigment mixing, pesticide manufacturing and other fields to meet the mixing and stirring needs of different industries.

According to the material, the automatic lifting hopper mixer can be divided into two types: carbon steel and stainless steel:

Carbon steel automatic lifting hopper mixer: It isusually made of carbon steel, with good strength and wear resistance, suitable for material mixing needs in general industrial environments, relatively low price, easy to maintain and clean. Stainless steel automatic lifting hopper mixer: It ismade of stainless steel, with excellent corrosion resistance and hygiene, often used in food, pharmaceutical and other industries with high hygiene requirements, easy to clean and disinfect, relatively high price.

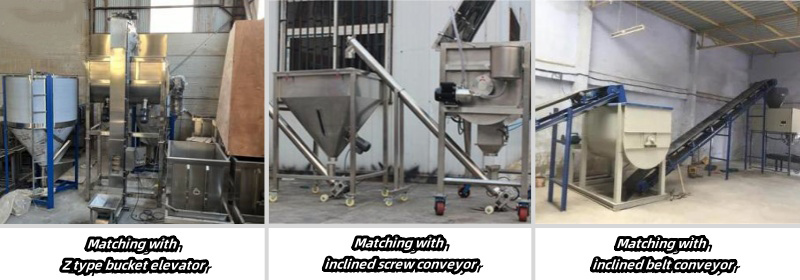

Three equipment types matched with automatic lifting hopper mixer:

Matching with Z type bucket elevator: When used with the automatic lifting hopper mixer, the Z type bucket elevator can transport raw materials from the bottom to the mixer hopper to achieve automatic feeding.

Matching with inclined screw conveyor: When used with the automatic lifting hopper mixer, the inclined screw conveyor can transport materials to the mixer to achieve material transportation and mixing, which is suitable for various industrial production scenarios.

Matching with inclined belt conveyor: When used with the automatic lifting hopper mixer, the inclined belt conveyor can efficiently transport materials to the mixer to achieve continuous transportation and mixing of materials.

The working principle of the automatic lifting hopper mixer is as follows:

Lifting mechanism: The automatic lifting hopper mixer realizes the vertical movement of the hopper through the lifting mechanism. Lifting mechanisms usually consist of motors, transmission devices and guide rails. The motor provides power, and the transmission converts the motor's rotational motion into linear motion, allowing the hopper to rise or fall to the required height.

Mixing device: The automatic lifting hopper mixer is equipped with a mixing device, usually one or more agitators. The agitator can be spiral, paddle-shaped or other shapes, and stirs and mixes the materials through rotational motion. The rotation speed and direction of the mixer can be adjusted as needed to achieve different mixing requirements.

Control system: The automatic lifting hopper mixer is equipped with a control system to control the operation of the lifting mechanism and mixing device. The control system can be operated via a control panel or computer. The operator can set parameters such as mixing time, speed and lifting height, and monitor the status of the mixing process.

During the working process, the materials to be mixed are first put into the hopper. Then, set parameters such as mixing time, speed, and lifting height as needed. After starting the mixer, the lifting mechanism raises the hopper to an appropriate height so that the mixer is in contact with the material. The agitator starts to rotate, and the hopper can also be raised and lowered as needed to ensure full contact and mixing between the agitator and the material. After the mixing is completed, the hopper can be lowered to a suitable position to take out the mixed materials.

Efficient automation

The automatic lifting hopper mixer has automation functions and can realize automatic operation by setting parameters and control system. This greatly improves production efficiency, reduces labor input and operation time, and reduces the risk of human error.

Flexible height adjustment

The automatic lifting hopper mixer has an adjustable height function to adapt to different container height requirements. It can flexibly adjust the contact position between the mixer and the material according to the needs of the production process to ensure mixing uniformity and improve the mixing effect.

Uniform mixing effect

The automatic lifting hopper mixer can fully mix the materials through the rotation and shearing force of the mixer. The design and movement of the agitator ensure the uniformity of the material, avoid stratification or aggregation of materials in different parts, and improve the mixing effect and product quality.

Multifunctional application

The automatic lifting hopper mixer is suitable for mixing a variety of materials, including powders, granules, liquids, etc. It can be widely used in chemical, pharmaceutical, food and other industries to meet the mixing and stirring needs of different industries.

Easy and safe operation

The operation of the automatic lifting hopper mixer is usually carried out through the control panel or computer, and the operation is simple and convenient. At the same time, it is equipped with safety protection devices, such as protective covers, emergency stop buttons, etc., to ensure the safety of operators.

Improve production quality

Through uniform mixing and automated operation, automatic lifting hopper mixers can improve production quality. It ensures the consistency and uniformity of materials, reduces the problem of uneven or incomplete mixing, and improves the quality stability and reliability of the product.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

A pharmaceutical company needs to blend different drug ingredients during the manufacturing process to ensure product quality and consistency. In order to improve mixing efficiency and reduce the risk of manual operation, they chose to introduce an automatic lifting hopper mixer. The automatic lifting hopper mixer has an adjustable height function and can adapt to different container height requirements. The operator only needs to simply set the mixing parameters, and the mixer can automatically complete the mixing process.

This pharmaceutical company has experienced significant benefits after using an automatic lift hopper mixer. First, the mixing process becomes more efficient, greatly shortening mixing time and improving production efficiency. Secondly, due to the rotation and shear force of the mixer, the pharmaceutical ingredients can be fully mixed, ensuring the uniformity and consistency of the mixing and improving product quality. Additionally, automated operations reduce the risk of human error and provide a safer working environment.

Xinxiang Dahan automatic lifting hopper mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the automatic lifting hopper mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The automatic lifting hopper mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan automatic lifting hopper mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. is one of the trustworthy automatic lifting hopper mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.